The UP1200 is a multi-purpose, continuous flow, Reflow Soldering Oven capable of temperatures up to 400°C. Designed to process up to 300mm wafers and any application requiring full chamber cover gas with <5ppm O2 levels across all zones, virtually no vibration, and complete profile customization. Utilizing Sikama’s unique contact conduction heating in combination with thermal convection and radiant heating which provides unmatched thermal energy transfer and the lowest energy use of any comparable reflow oven.

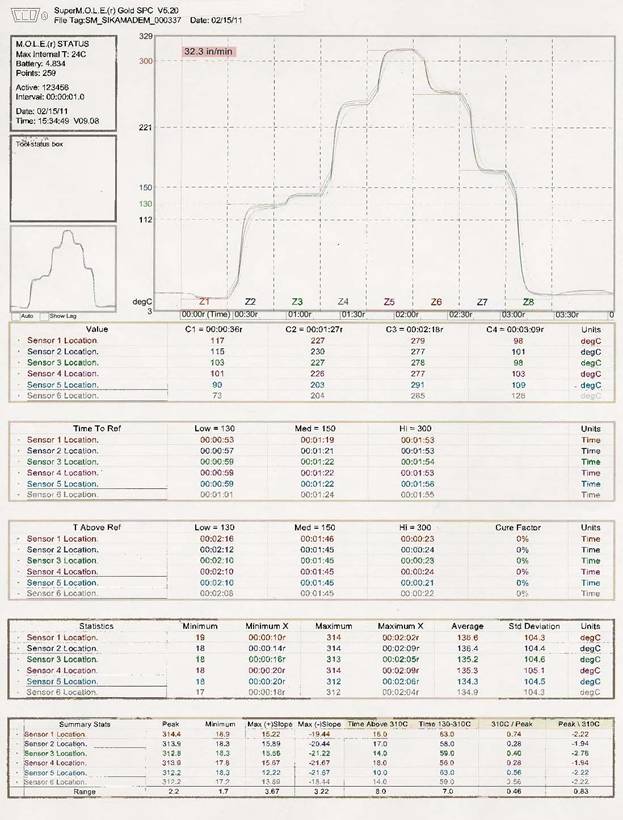

With eight work zones internal to the oven, six heat zones, and two cooling zones, users can achieve complete control over profiles in the smallest footprint in the industry. We provide full SECS/GEM and SMEMA capabilities to allow easy integration into automated production lines and SPC data capture.

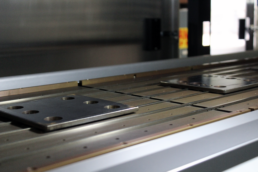

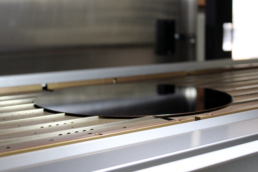

The UP1200 is built with either a walking beam transport or the LIFT system that accommodates warped wafers and heavier components. Both transport systems move the work item from zone to zone through the oven without friction or vibration. Each system lifts the component above the bottom contact heating zones and carries it to the next zone. The work item is not dragged or pushed, reducing the possibility of damage due to scraping, scratching, or vibration.

No other oven provides these levels of carbon-conscious performance with a space-saving footprint.

Click here to watch on YouTube.

Datasheet Download

Fill out the form below to download Sikama International's Datasheets

Thank you!

You have successfully joined our subscriber list.

UP1200

The UP1200 is a multi-purpose, continuous flow, Reflow Soldering Oven capable of temperatures up to 400°C. Designed to process up to 300mm wafers and any application requiring full chamber cover gas with <5ppm O2 levels across all zones, virtually no vibration, and complete profile customization. Utilizing Sikama’s unique contact conduction heating in combination with thermal convection and radiant heating which provides unmatched thermal energy transfer and the lowest energy use of any comparable reflow oven. This product is CE certified and meets SEMI safety and ergometric standards.