Technology

Sikama is dedicated to technology first as our strong foundation in engineering combined with product development yield the highest performing and most robust machine on the market.

More support, less cost

With vertically integrated manufacturing based in Southern California, Sikama offers the highest levels of customer support and product flexibility, all while keeping our costs as low as possible to offer the best value to our customers.

More service, less uncertainty

Sikama’s on-site lab offers complimentary on-site testing and metrology for our customers. Whether you send us your parts or visit our factory, we will ensure that our equipment is the perfect fit for your application.

More integration, less oversight

Sikama’s products are fully SECS/GEM and SMEMA compatible, so you can be sure that whatever your automation needs may be, our products will offer the maximum in automation capabilities.

More efficiency, less time

Sikama’s unique conduction plus convection and radiant heating provides industry leading heating and cooling efficiencies. Direct contact thermal transfer allows efficient heating and cooling of the most demanding substrates, including high mass, tall height, and unique geometry.

More configurability, less floor space

Sikama’s reflow and shuttle systems are built with floorspace in mind utilizing zone by zone heating and cooling with configurable products dwell times allowing maximum configurability for any manufacturing space.

Higher throughput, less facility requirements

Sikama’s conduction heating and low volume inert environment chamber combined with zone by zone dwell times, your electricity and gas requirements are much lower than the competition while still providing <10ppm O2 levels and +/- 2C temperature control in the industry.

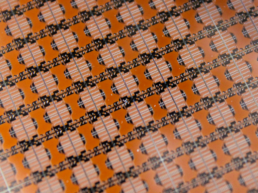

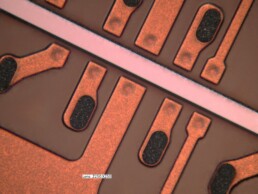

With our metrology capabilities up to 2500x magnification, Sikama International can closely analyze how our reflow ovens process wafers with 3D imaging.