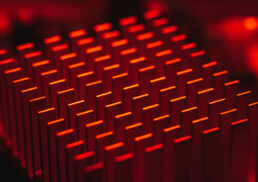

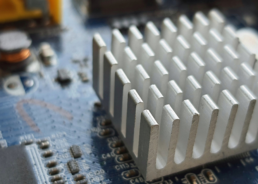

Sikama’s silver and copper sintering pre-dry ovens offer conductive heating in an environment with as low as 5ppm O2 levels utilizing a footprint of less than 10 square feet (1 square meter). You no longer must choose between cost, space, or power for your pre-drying needs. Rather, with Sikama International’s compact design, highly efficient thermal transfer to high-mass components, and the lowest carbon footprint in the industry, our products are the perfect fit for your sintering production line.

Additionally, with only 15 minutes before reaching temperature set points, your energy costs and gas requirements are kept to a minimum.

With SMEMA and SECS/GEM capability and recipe-driven customizable profiling, our Ultra Profile and Falcon series ovens seamlessly integrate into your automated production line. Sikama provides accurate and consistent temperatures, with each zone fully customizable to within 1°C in each heating zone. Liquid-cooled zones also provide controlled cooling rates.

With multidirectional process flow using either sweeper bar or walking beam transport systems and the lowest power consumption in the industry, Sikama has a configuration for any need.

For over 40 years Sikama International has offered highly reliable equipment and is the trusted option of manufacturers worldwide.

Datasheet Download

Fill out the form below to download Sikama International's Datasheets

Thank you!

You have successfully joined our subscriber list.

Sintering

Sikama’s silver and copper sintering pre-dry ovens offer conductive heating in an environment with as low as 5ppm O2 levels utilizing a footprint of less than 10 square feet (1 square meter). You no longer must choose between cost, space, or power for your pre-drying needs. Rather, with Sikama International’s compact design, highly efficient thermal transfer to high-mass components, and the lowest carbon footprint in the industry, our products are the perfect fit for your sintering production line. With 15 minutes before reaching temperature set-points, your energy costs and gas requirements are kept to a minimum. Alongside SMEMA and SECS/GEM capability, multidirectional process flow, and recipe-driven customizable profiling, seamless integration, lower energy costs and gas requirements, Sikama has a configuration for any need.